Actionable Tactics and Clear Goals

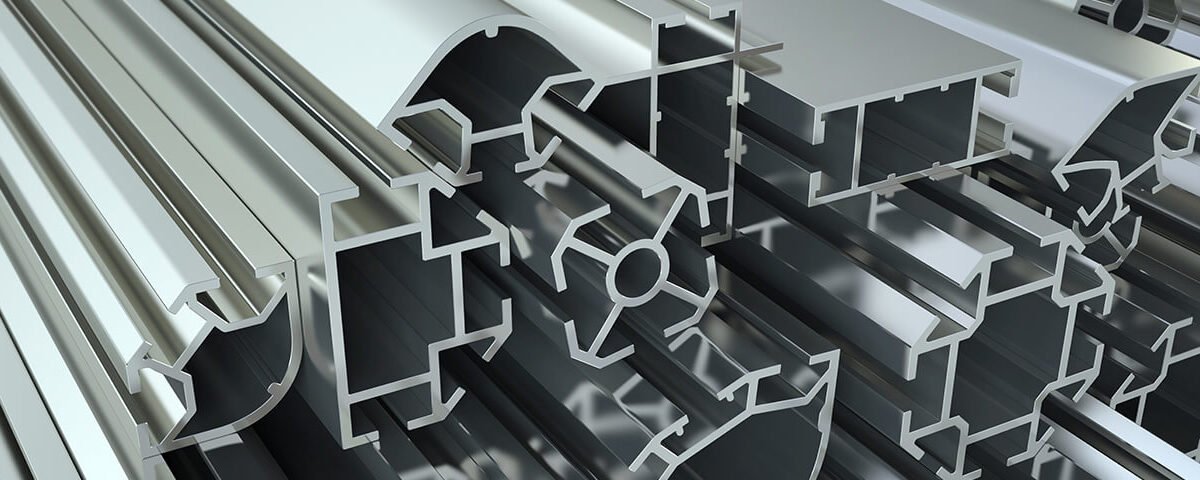

In the dynamic world of aluminum extrusion, having a clear strategy, actionable tactics, and well-defined goals is essential for success. By focusing on innovation, customer-centric solutions, and sustainability, companies can meet the ever-growing demands of their clients while staying ahead of the competition.

Whether you're seeking a trusted partner for a new aluminum project or need additional support to expand your capacity, we’re here to provide reliable solutions tailored to your needs.

Strategic Vision

A strong strategy is based on providing precision-engineered solutions for various industries, such as construction, infrastructure, and specialized manufacturing. The goal is to be the preferred partner for businesses seeking high-quality aluminum extrusion products and services. This approach is underpinned by three core principles:

-

Customer-Centric Innovation

- Focus on continuously innovating to meet changing customer needs.

- Deliver precision, customization, and reliability to help clients excel in their markets.

-

Sustainability and Efficiency

- Prioritize eco-friendly practices, from material sourcing to waste reduction in manufacturing.

- Invest in energy-efficient technologies to drive down costs and reduce the environmental impact.

-

Long-Term Partnerships

- Build and nurture long-lasting partnerships with suppliers, designers, and clients by providing top-tier service and superior product quality.

- Strengthen relationships with key suppliers to ensure exclusivity and consistent product availability.

Tactics to Drive Success

To achieve strategic goals, effective tactics must be put into action. Below are some key approaches to ensure success:

Expand Industry Reach

- Target growth in the construction and infrastructure sectors, where the demand for durable, lightweight aluminum products continues to rise.

- Implement specialized marketing and sales strategies to engage decision-makers within these industries.

Streamlined Design-to-Delivery Process

- Leverage the four core pillars of Design, Extrude, Fabricate, and Finish to deliver a fully integrated service, from concept to completion.

- Optimize project timelines, ensuring customers receive faster and more efficient solutions.

Technology Investments

- Invest in state-of-the-art extrusion equipment and automation to enhance precision, reduce costs, and increase production speed.

- Adopt advanced CAD/CAM systems to offer more complex designs and ensure a high level of customization for clients.

Employee Development

- Provide ongoing training to ensure the workforce is well-versed in the latest technologies, safety standards, and customer service best practices.

- Foster a culture of innovation and continuous improvement within the organization.

Sustainability Practices

- Enhance recycling programs and prioritize eco-friendly production methods in line with global sustainability trends.

- Explore and utilize aluminum alloys that offer superior strength, lighter weight, and lower environmental impact.

Defining Clear Goals

To stay on track and measure progress, it’s important to set specific, measurable goals for the next five years:

Increase Market Share by 20%

- Target growth in key sectors such as construction and infrastructure, focusing on increasing market presence across Canada.

Achieve Zero-Waste Manufacturing

- By 2026, implement a comprehensive zero-waste strategy, ensuring all production by-products are recycled or reused.

Expand Product Line

- Develop new products tailored to emerging trends in green building and architectural design, highlighting aluminum’s sustainability benefits.

Double the Customer Base

- Through targeted marketing and exceptional service, aim to double the number of clients by 2027.

Improve Customer Satisfaction by 30%

- Enhance customer experience through technology and training, with a goal of increasing satisfaction ratings by 30% within the next three years.

The Path Forward

By setting ambitious goals and following a clear, adaptable strategy, companies in the aluminum extrusion industry can continue to innovate and grow. Prioritizing efficiency, sustainability, and customer satisfaction ensures long-term success in a competitive landscape.

Looking ahead, the focus will remain on delivering high-quality solutions, building lasting partnerships, and creating a more sustainable future through innovative aluminum extrusion practices.

-

"As the Manager of Director, I’m proud of the direction we’re heading. Our focus on innovation, sustainability, and efficiency aligns perfectly with the evolving needs of our clients and the industry. Every step we take, from investing in advanced technologies to enhancing our recycling initiatives, is driven by our commitment to delivering the best possible service and product quality. The goals we’ve outlined are ambitious, but I’m confident that our dedicated team will continue to exceed expectations and solidify our

Le Dam,Manager Director -

"As Founder and President, sustainability has always been a core value for our company. From the very beginning, we recognized the critical importance of reducing our environmental footprint, and that commitment has only strengthened over time. Today, we are proud to lead the way in implementing innovative recycling practices and sustainable manufacturing processes within the aluminum extrusion industry. Our goal to achieve zero-waste production is not just about efficiency—it's about responsibility. By adopting advanced recycling methods and using eco-friendly materials,

Jason Dam,Founder & President -

"As Founder and Manager, I am proud to be part of a company that prioritizes sustainability and environmental responsibility in everything we do. Our dedication to sustainable practices is not just about meeting industry standards—it’s about leading the way. By focusing on recycling, reducing waste, and using eco-friendly materials, we are ensuring that our operations are both efficient and environmentally conscious. Our commitment to minimizing our environmental footprint is reflected in every stage of our process, from design to production.

Dzung Do,Founder & Manager

Jili1bet has a good selection of slot games, especially for Jili fans. The site is well laid out, making it easy to find what you’re looking for. Spin some reels at jili1bet