Precision Engineering Solutions and Processes

Precision engineering is at the core of everything we do, ensuring that even the smallest details make a significant difference in the performance and reliability of aluminum extrusions. Our team of highly skilled engineers uses the latest design technology and advanced manufacturing techniques to ensure every product is crafted to exact specifications.

Whether you're seeking a trusted partner for a new aluminum project or need additional support to expand your capacity, we’re here to provide reliable solutions tailored to your needs.

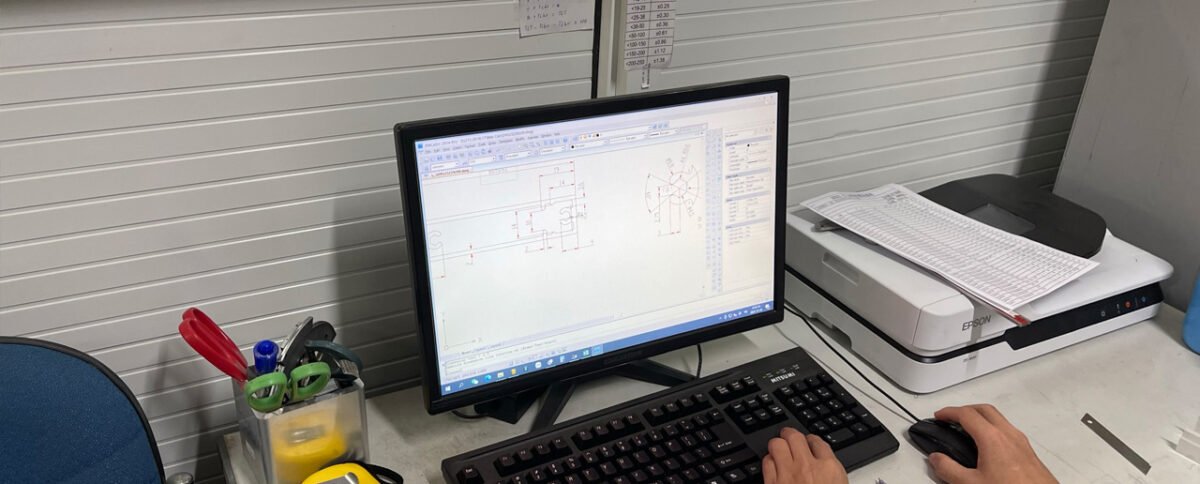

Advanced Design Tools

The engineering process begins with state-of-the-art CAD (Computer-Aided Design) software, allowing us to create highly detailed and accurate designs tailored to your project’s unique needs. This technology enables visualization of complex shapes, optimized material usage, and predictions of how products will perform in real-world applications. Every design is reviewed for functionality, efficiency, and manufacturability before moving into production.

Uncompromising Accuracy

Once the design is finalized, precision manufacturing processes take over. Cutting-edge extrusion machines are capable of producing aluminum profiles with intricate shapes and tight tolerances. Whether your project requires simple profiles or highly complex shapes, the machinery ensures that each product is made with the highest level of accuracy, meeting your exact requirements every time.

Rigorous Testing and Quality Control

Precision engineering doesn’t stop at manufacturing. Every product undergoes rigorous quality control measures, where it is inspected and tested for dimensional accuracy, strength, and durability. Advanced measuring instruments are used to verify that each extrusion meets precise standards. This commitment to precision ensures that the products perform as expected in their final applications.

Customization and Flexibility

The engineering capabilities allow for an incredible level of customization. Working closely with clients, solutions are developed specifically tailored to unique needs, no matter how complex. From adjusting alloy composition to creating custom dies, the expertise to deliver the perfect solution for any project is always available.

Innovation in Every Step

Precision engineering also means staying ahead of trends. New technologies and processes are continually invested in to enhance the ability to deliver innovative, high-quality products. This forward-thinking approach ensures that evolving demands are met while maintaining high standards of quality.

Efficiency and Cost-Effectiveness

By focusing on precision engineering, not only is product quality improved, but efficiency is enhanced. Attention to detail reduces material waste, streamlines production processes, and ensures faster turnaround times. This level of precision allows for cost-effective solutions without compromising on quality or performance.

Why Precision Engineering Matters

Choosing precision-engineered solutions means partnering with a team that values accuracy, quality, and innovation. The focus on precision ensures that every aluminum extrusion meets and exceeds project demands. Whether reliable components are needed for complex applications or durable products for long-term use, precision engineering guarantees optimal performance and exceptional results.

-

"As the Manager of Director, I’m proud of the direction we’re heading. Our focus on innovation, sustainability, and efficiency aligns perfectly with the evolving needs of our clients and the industry. Every step we take, from investing in advanced technologies to enhancing our recycling initiatives, is driven by our commitment to delivering the best possible service and product quality. The goals we’ve outlined are ambitious, but I’m confident that our dedicated team will continue to exceed expectations and solidify our

Le Dam,Manager Director -

"As Founder and President, sustainability has always been a core value for our company. From the very beginning, we recognized the critical importance of reducing our environmental footprint, and that commitment has only strengthened over time. Today, we are proud to lead the way in implementing innovative recycling practices and sustainable manufacturing processes within the aluminum extrusion industry. Our goal to achieve zero-waste production is not just about efficiency—it's about responsibility. By adopting advanced recycling methods and using eco-friendly materials,

Jason Dam,Founder & President -

"As Founder and Manager, I am proud to be part of a company that prioritizes sustainability and environmental responsibility in everything we do. Our dedication to sustainable practices is not just about meeting industry standards—it’s about leading the way. By focusing on recycling, reducing waste, and using eco-friendly materials, we are ensuring that our operations are both efficient and environmentally conscious. Our commitment to minimizing our environmental footprint is reflected in every stage of our process, from design to production.

Dzung Do,Founder & Manager