Leading with Aluminum Extrusion, Sustainability, and Energy Efficiency

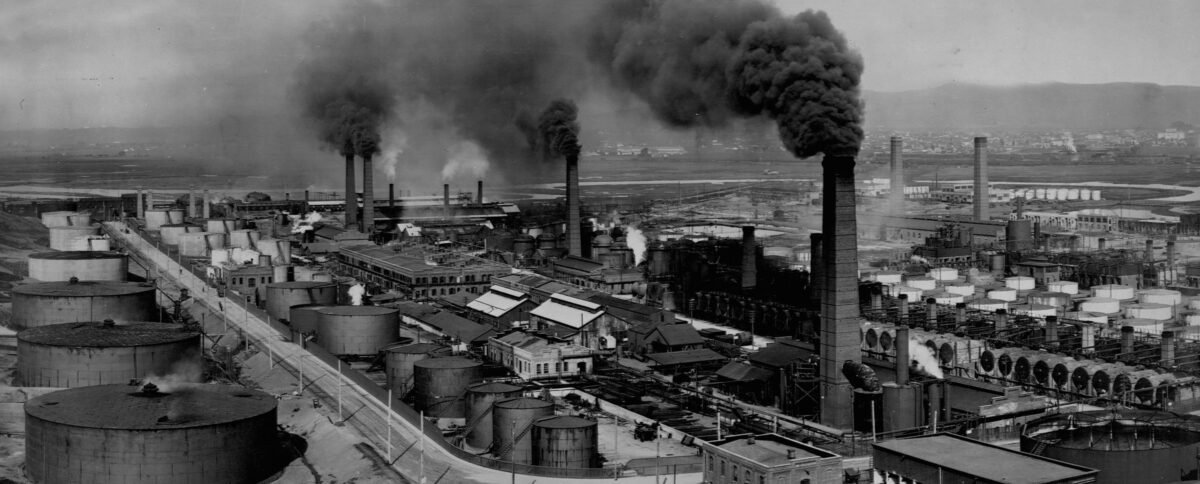

What can the evolution of industrialization, past and present, teach us about the future of manufacturing and its impact on the environment? As we enter a new phase of industrial growth, the focus is shifting from sheer productivity to sustainable, energy-efficient practices that safeguard the planet.

In many ways, today’s aluminum extrusion industry mirrors the technological innovations of the original Industrial Revolution, but with a crucial difference: we now recognize the need to balance economic growth with environmental responsibility. Aluminum, with its inherent recyclability and light weight, has become a cornerstone of this modern industrial era—offering manufacturers a solution that not only meets the demands for durability and precision but also contributes to significant energy savings.

Sustainability at the Core

The environmental consequences of rapid industrialization, as seen in past centuries, are undeniable. But as industries continue to expand, the path forward must include sustainable practices that minimize damage to ecosystems. Modern manufacturing, including aluminum extrusion, is leading this charge by integrating energy-saving technologies and prioritizing recyclable materials.

Unlike the unchecked pollution of previous industrial revolutions, today’s production processes can leverage recycled aluminum, which requires only 5% of the energy needed to produce new aluminum from raw materials. This energy reduction translates directly into fewer carbon emissions and less strain on the environment, making aluminum one of the most eco-friendly materials in industrial use today.

Aluminum Extrusion: Precision with Purpose

Beyond sustainability, aluminum extrusion also offers unmatched versatility in modern manufacturing. Its ability to be molded into intricate, custom shapes while maintaining strength and flexibility makes it the ideal material for industries such as construction, infrastructure, and transportation. By offering lightweight solutions, aluminum products also contribute to energy efficiency in end-use applications, such as reducing fuel consumption in transportation and enhancing the thermal efficiency of buildings.

As global industries continue to evolve, aluminum is at the forefront of this new wave, pushing the boundaries of what materials can do while embracing environmentally friendly methods.

Energy Efficiency: A New Industrial Standard

Energy efficiency is no longer a byproduct of manufacturing innovation—it is now a driving force. Companies that incorporate aluminum into their operations are actively reducing their energy consumption, not only in the production process but also in the lifetime of the products themselves. Aluminum extrusions, for example, are used in energy-efficient buildings and transportation solutions that contribute to a greener future.

By focusing on reducing waste and optimizing energy use, manufacturers can take meaningful steps to reverse the environmental damage caused by previous waves of industrialization. In today’s world, where the effects of climate change are evident, businesses have a responsibility to adopt sustainable methods that prioritize energy conservation.

A Future Built on Responsibility

Just as James Watt and his contemporaries once revolutionized industry with the invention of the steam engine, today’s innovators are redefining industrialization through sustainable practices and technological advancements. Aluminum extrusion, with its combination of precision engineering, recyclability, and energy-saving potential, is playing a pivotal role in this transformation.

As industries across the globe face the challenges of a warming planet, we are proud to be at the forefront of a responsible, eco-friendly revolution—creating solutions that not only meet the demands of modern manufacturing but also ensure a healthier planet for generations to come.